- Who we are

-

-

In February 2007, the company was acquired by the ARA Group and became Environmental Automation.

EA has a national client base and is dedicated to tailoring building automation systems to suit our clients’ specific requirements.

-

- About us

- Our people

- Cultural Engagement

- Brand & Product Portfolio

Featured Project

Environmental Automation was able to significantly increase energy savings by retrofit to Reliable Controls seamlessly within the building network. Click here to read more

-

-

- What we do

-

-

Our wide range of automation and access control products ensures we can provide the best solution for any building application.

This includes management of the building’s heating and cooling, security access, lifts, lighting and more.

-

- Building Management Systems (BMS)

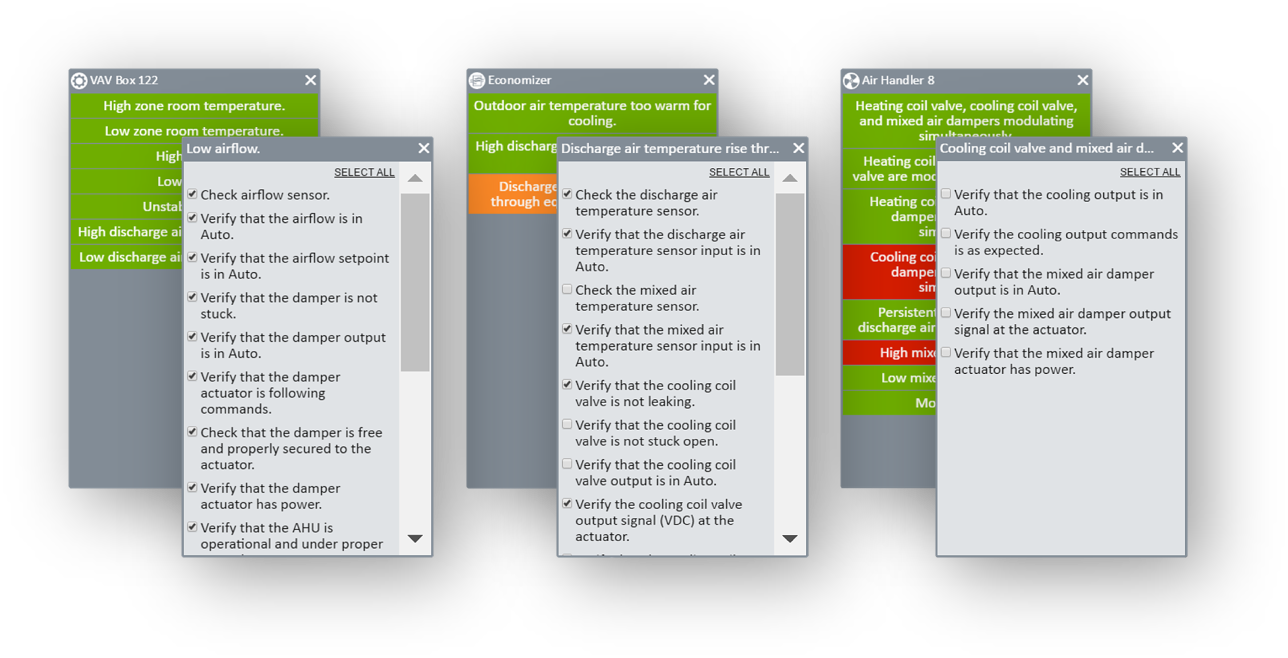

- Integrated Fault Detection Diagnostics (IFDD)

- EA Plus

- Brand & Product Portfolio

Featured Project

Environmental Automation was able to significantly increase energy savings by retrofit to Reliable Controls seamlessly within the building network. Click here to read more

-

-

- Careers

- contact us

See all results for '{phrase}'

Can't find what you're looking

Displaying {results_count} results of {results_count_total}